Whether derived naturally from a tree or synthetically from petroleum products rubber has several characteristics that make it a valuable and widely used industrial product.

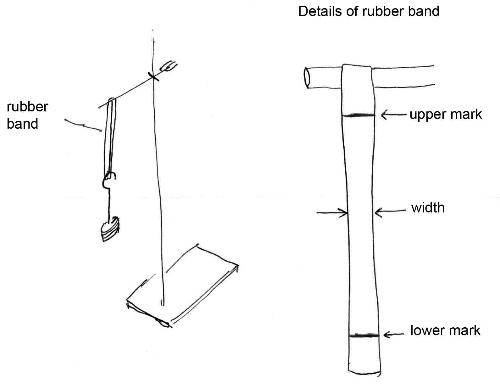

Characteristics of rubber band.

One of its most unique characteristics is that when developed at very low properties down to 65ᵒ fahrenheit it remains functional because it becomes leathery in its consistency.

Silicone rubber compounds have characteristics of both inorganic and organic materials and offer a number of advantages not found in other organic rubbers.

This rubber materials comparison chart gives you key factors in your choice of rubber mechanical properties.

When raw rubber is heated it becomes sticky and when it is in colder temperatures it tends to break just like the synthetic variety.

The rubber band can slip relative to the wooden axle preventing the wheels from spinning.

Even if the wheels do spin there might not be enough friction with the ground causing them to spin in.

For example if you need to find rubber compression properties rubber weather.

It s tough tires resists water and chemicals gloves elastic rubber bands and much more.

Notable developments in the evolution of rubber bands began in 1923 when william h.

As rubber band is made up from rubber it possess properties of rubber.

Most rubber bands are manufactured out of natural rubber or especially at larger sizes elastomer and are sold in a variety of sizes.

Or better yet use the rubber chart to find which material will best suit your environment.

A rubber band is a loop of rubber usually ring shaped and commonly used to hold multiple objects together.

Depending on the material a resistance band will be more likely to overstretch or tear.

Rubber is quite stretchy as indicated by the nature of rubber bands.

Spencer obtained a few goodyear inner tubes and cut the bands by hand in his basement where he.

The most common properties of rubber are its elasticity resistance to water and its use as an electrical insulator.

Although most resistance bands are made of some kind of rubber like tubing the materials used can actually vary greatly.

Harder rubber usually has a higher tensile modulus making it more resilient.

Whenever you stretched rubber or rubber band it gets stretched when you.

Aflas rubber is used mostly for the various parts associated with the oil drilling equipment.

Sticking with a genuine rubber latex blend is usually a good call.

Tensile modulus is the stress or force required for producing a strain or an elongation percentage in a rubber sample.

Although it sounds similar to tensile strength the properties are different.

The rubber band was patented in england on march 17 1845 by stephen perry.